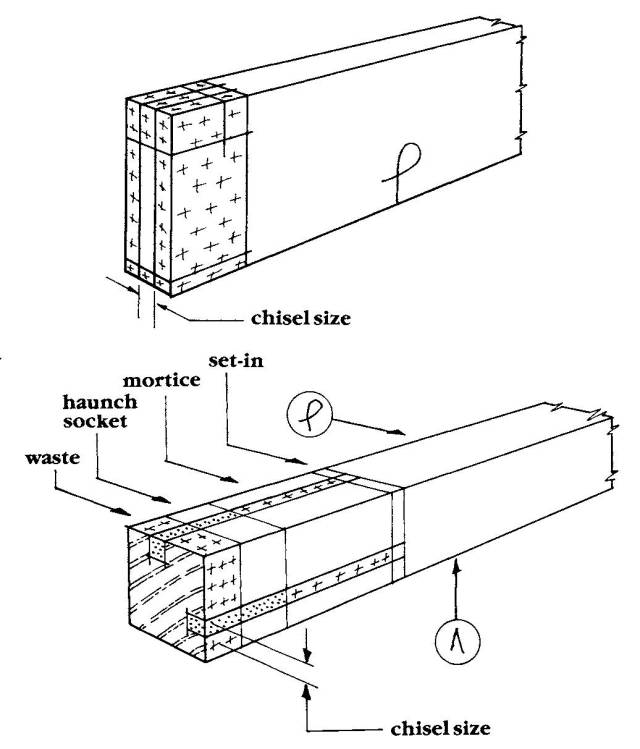

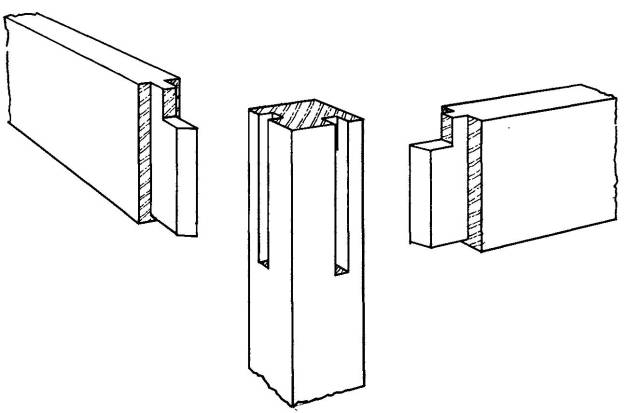

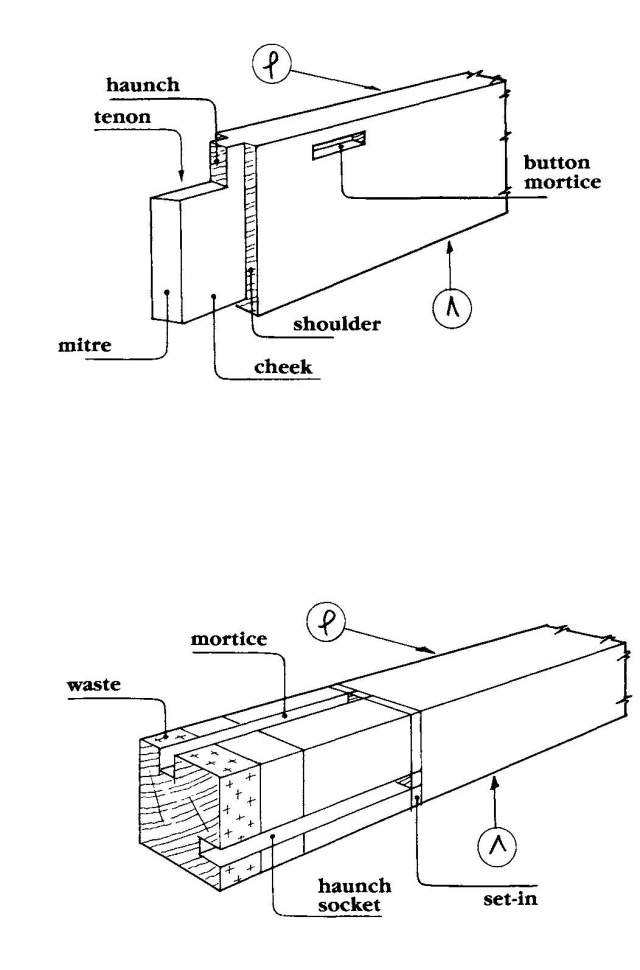

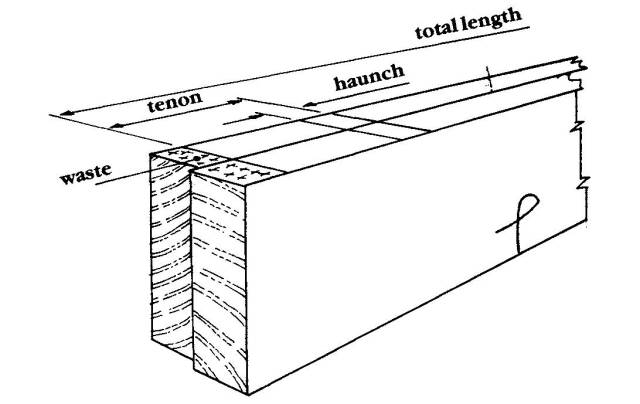

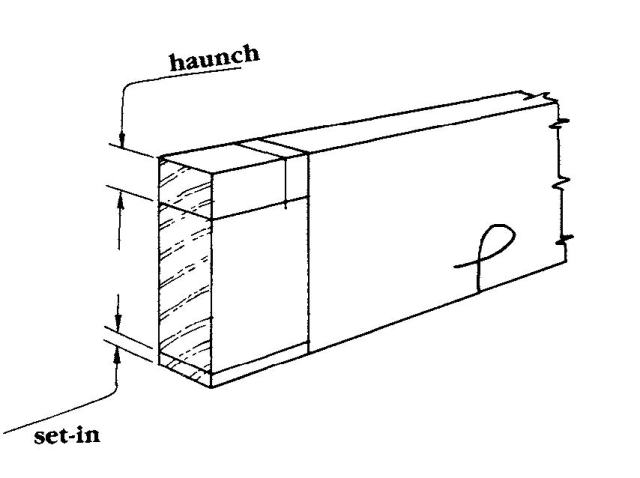

In a table or stool construction either the legs or the rails may be marked out first. This example starts with the rails. Cramp together the long and short pairs, with true faces out and true edges down. Mark each end with a knife and square (Fig 96). Then uncramp the pairs, square round the lines (Fig 97), and carefully saw off the waste. It is important to saw this cleanly in order to be able to gauge nicely on the end later. First gauge the set-in, at about 3mm (1/8in.), and then the haunch (Fig 98). The set-in is purely cosmetic, to conceal any irregularity in the joint.

The haunch provides a bridge at the top of the leg, helping to prevent the mortice splitting and at the same time, by its added width to the tenon, reducing the possibility of the rail twisting in the leg. The haunch should be about a quarter of the tenon width. Some writers will say a third but this seems to reduce the tenon too much.

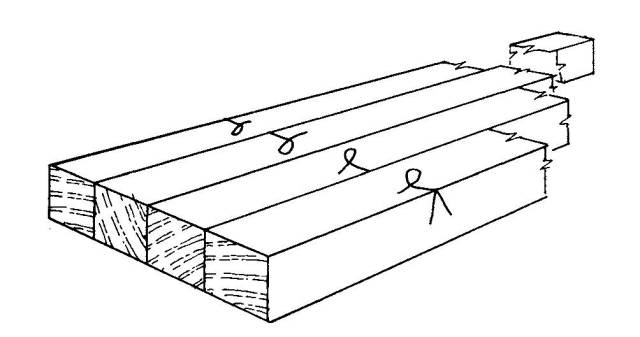

To mark out the legs, put them together with the faces and edges as shown (Fig 99) then turn them over and mark them on a blank face. Mark the total length, leaving some waste (which should be shaded) at each end. The waste must be about 20mm (3/4in.) at the top or jointed end.

Offer up the rail, and from it mark the haunch, set-in and rail width (Fig 100), square these across and uncramp. Square these lines onto the other blank face. The total length lines are squared right round (Fig 101).

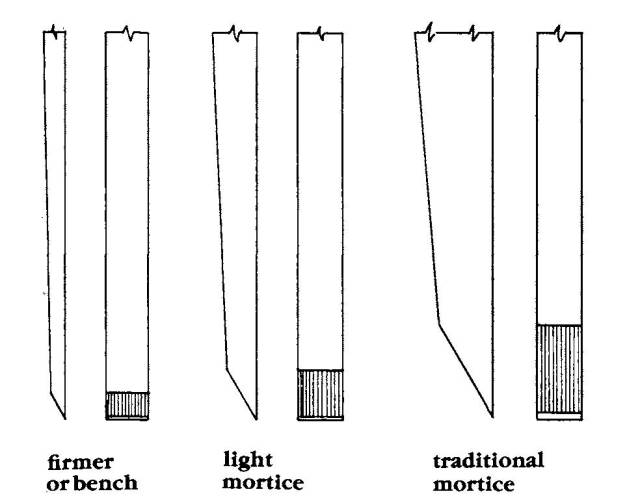

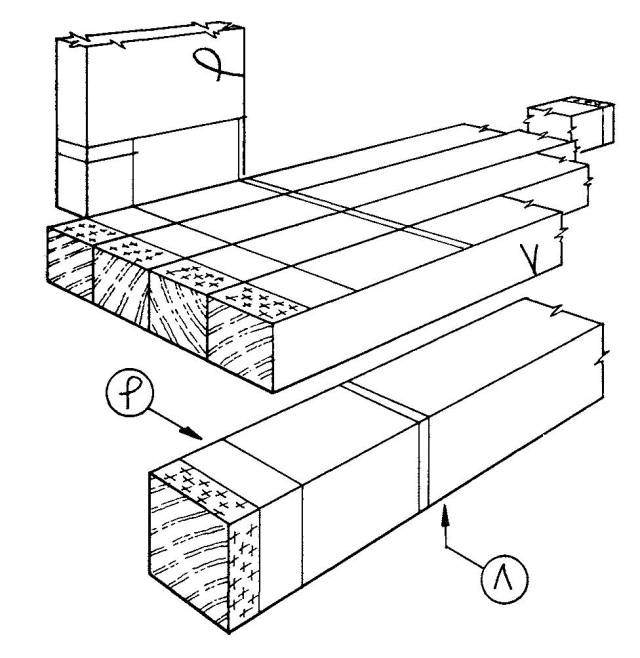

The thickness of a tenon is normally about one third of the rail thickness. It is not taken from measurement but is the size of the nearest available chisel to this size. The traditional hand mortice chisels vary considerably from the nominal size. Machine chisels are quite accurate and are now becoming metric. Hand mortice chisels are much thicker than the common firmer or bench chisel (Fig 102), which is very liable to break when levering. The extra thickness of the mortice chisel is also a help in preventing it from twisting.

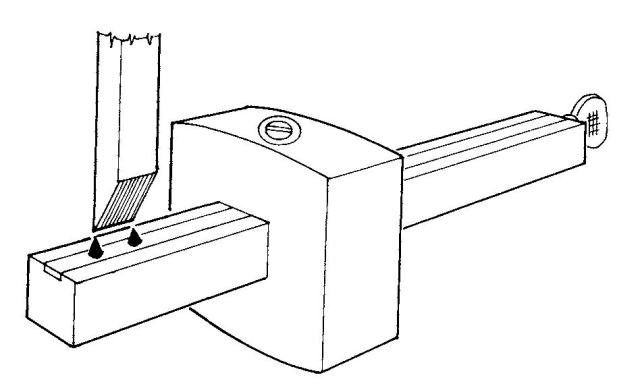

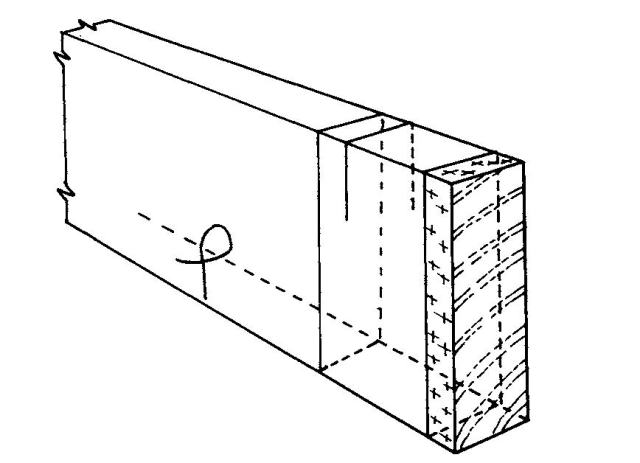

Set the mortice gauge carefully to the chisel (Fig 103) then set to its position on the rail, commonly central. Without changing the setting, mark out the mortices on the legs (Fig 104), gauging from the true face and the true edge. Mark the tenons similarly, gauging from the true face.

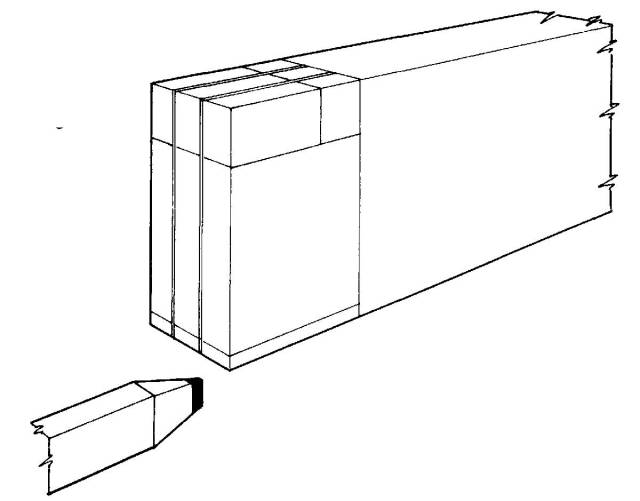

Beginners will find it helpful later on, when sawing the tenons, if a thick, soft pencil is run in the gauge marks. This produces a double pencil mark (Fig 105). The waste should be very clearly marked with pencil, generally by diagonal shading. (The method adopted in the illustrations is to avoid confusion with the end grain, and is not typical.)

Note: It is a good idea to number the joints to avoid confusion. This should be done on parts not involved in the cleaning-up process.

— Robert Wearing, from Chapter 2 of “The Essential Woodworker”