We began production of our Type 2 Dividers this week, and we hope to begin selling them in June or July.

As long-time customers know, we struggled to produce the first version of these dividers. They were beautiful. They functioned very well. But they were difficult to manufacture in great volume. While we were charging $185 per pair, we probably should have charged $285 or more because of all the hand-fitting and hand-polishing.

So we took the dividers out of production and have been tinkering with them for some time.

OK, so the next part of this story is what you don’t ever get to read when it comes to tool production. Many toolmakers are loath to credit the designers and machinists who figure out the nitty-gritty stuff. I want to give them their due.

Last year, we began working with Josh Cook, a mechanical designer and woodworker who was really interested in our original dividers. He sent me a pair that he’d made based on photos from our website. And we went from there.

Enter machinist Craig Jackson of Machine Time. You might know Craig as the creator of the EasyWood turning tools, which I love. After the EasyWood business was sold to another party and things went south, Craig went back to high-tolerance part production. But he loves making woodworking tools. So he took pity on me and now works with Crucible on some of our tools.

Together the three of us worked through a bunch of variables to come up with a design for these dividers that is:

- Functionally perfect from the user’s point of view

- Easy to make with minimal setups on the mill

- Relatively inexpensive

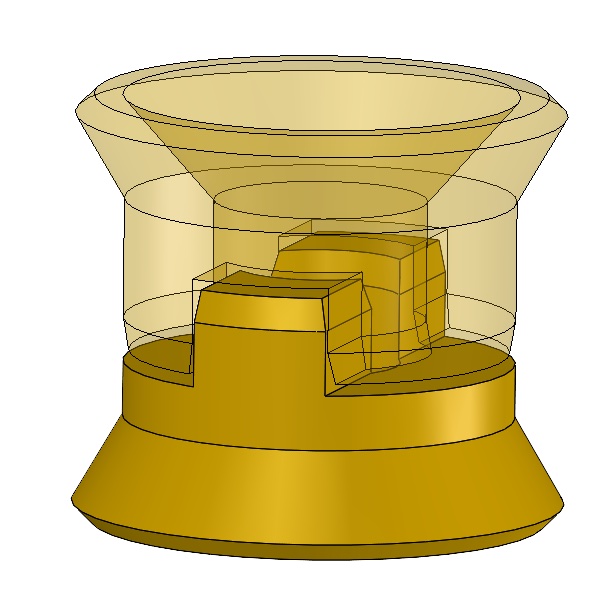

The Crucible Type 2 dividers are new from the ground up. I can promise you that they have the same feel in the hand – like a heavy and smooth stone you found on a riverbank. Ever since we finished the first pre-production versions, I have kept a pair at arm’s length.

The hinge is completely redesigned and astonishingly smooth in use. While the pointy legs of the dividers are the most visible aspect of the tool, the hinge might be the most difficult part to design and manufacture. After I-don’t-know-how-many iterations, the current hinge is (here’s a technical term) sweet. Its tension is adjusted with a No. 8 screwdriver – something every woodworker has. You can set the dividers to move stiffly and hold a setting. Or you can lock them down to rabidly maintain the position of the points.

We also wanted to make these as affordable as possible while still making them functionally and aesthetically great. And make them in the U.S. with U.S. materials. The goal was a $100 retail – a little less than you would pay for a Starrett compass.

On Tuesday, Craig called me to let me know that they were cranking out legs for the dividers. In a few weeks, hinges will begin production at another shop. If we have any luck, assembly will begin in June and we will start selling them shortly after.

Thank you for all your patience. It won’t be long now.

— Christopher Schwarz

P.S. I know that some of you are asking: Where is Raney Nelson in this? We parted ways amicably more than two years ago. Raney has evolved the design for the dividers to match his aesthetic. We have promoted his version many times on our blog this year and fully support his efforts at Daed Toolworks. If you are looking for ill will or grudges, you won’t find them here.