Rather than attempt to explain the specific details of French style trestle sawing, I have attempted to translate two the of the best primary French sources on sawing timber. The translations are not polished, but they will begin to help explain the methods used to mount heavy timbers on the chevalet type sawing trestle.

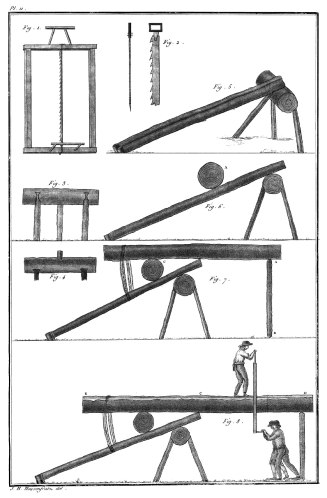

Long sawing, this is dividing a tree along its length with a saw. The saw, which is used, is formed of a steel blade, Plate II, fig. 1, held in a wooden frame. It is fixed with two iron rings, the rings are tightened by driving wedges to stiffen the blade. The teeth of the saw are curved, fig. 2, so that they will present an acute angle to the grain of the wood in order to tear and break it with ease. On the top and bottom of the saw are two handles which are used by the men to pull the saw in an up and down motion.

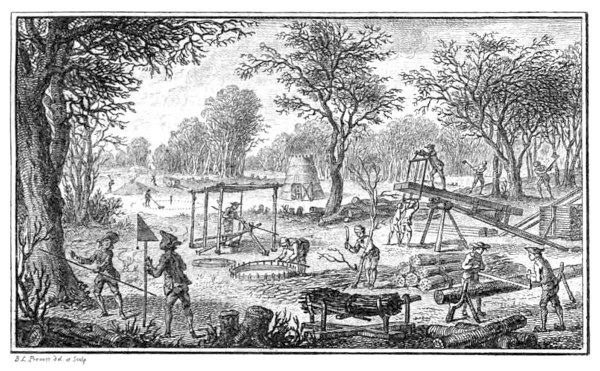

The common use of the long saw is on large tracts of land, where it is used to divide logs into planks and boards of different thicknesses. In many places the saw is worked by two men, in others by three. Generally the result obtained is proportional to the effort employed; three men add nearly fifty percent to the work of two; that is to say, if two sawyers divide 44 meters of oak plank four inches wide in a day, three sawyers should divide about 66.

To divide their wood, the long sawyers use a trestle, fig. 3 and 4, formed of a piece of timber in which three legs are fitted to support it. The piece does not require preparatory work, the feet are fitted with dovetails, because they are more sturdy. On this trestle is placed a pair of planks or two tree trunks on an incline, fig. 5; one end rests on the trestle and the other on the ground. The logs you wish to divide are rolled up these inclined timbers A , fig. 6.

After it has been rolled up to the end, the log is rotated back on itself until it is parallel and set level, fig. 7. a block of wood C is placed between the inclined timber and the horizontal workpiece. In this position, the log is fastened tightly to the inclined timber with ropes: one sawyer climbs up and the other two situate themselves below, fig. 8, and by their up and down motion, the saw divides the log along its length.

If the log is lengthy and the weight of the top sawyer makes it bend, a support is placed at its end AB, fig. 7, which sustains it and prevents it from bending. When the saw reaches the location of the support, it is shifted to the end of the log in order to continue the work. When the log is completely divided from the end CD, fig 8, it is turned with point C as its center and the end EC is presented to the action of the saw.

The main advantage of the scaffolding used by the forest long sawyers, is that two or three men can, from the lower end of the inclined timbers, roll the log, which is to be sawed, up to the top, and thence balance it on its center in some way, and rotate it on the point, to place the log in any position that the job requires.

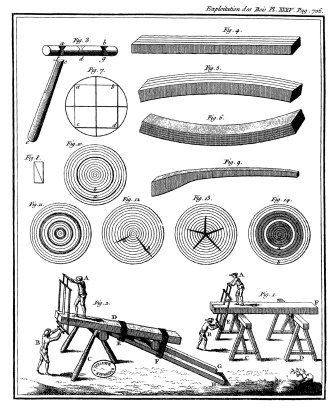

Prior to placing the workpiece on the scaffold, lines are made on the bark for the saw to follow. This operation is performed with the chalk line we discussed on page 126. Since the boards must generally be straight, the logs, for this sort of work, are selected from the straightest tree trunks, and when curves are encountered, they are often separated from the part intended to become boards; if the trees have a bit of curvature, they are rotated so that the curvature is in the direction of the length of the boards, and their width is straight.

Jean H. Hassenfratz

Traité de l’art du Charpentier – 1804

It is customary to begin by squaring those timbers with the axe, that are intended to be divided by the saw; however there are cases where it seems more appropriate to rip the timber with a saw without having it previously squared; that is what I will make known, after I briefly explain the work of the long sawyer.

On the manner of dividing timber with the long saw.

The long sawyers can not be less than two workers to perform their work; they are generally three, & this is not too many to mount large pieces on their chevalet. When such a workpiece has been placed, a worker A (Pl. XXXV. Fig. 1 & 2), mounts this piece, raising the saw, leads on the stroke, one or two others, placed beneath the piece, who pull the saw from below; & and the teeth of the saw bite down, it takes more force to pull the saw down than to raise it back up, it is for this reason that there are usually two workers below.

I say that the teeth of the saw only bite into the wood on descent, not only because the teeth are hooked in this direction and will not bite on rising, but also because long sawyers separate the wood chips from the kerf on the return stroke, that they must press down on in the descent.

The first operation of the long sawyers, consists of setting the workpiece on the chevalet (Fig 2.), or on the trestles (Fig 1.), for this workpiece must be high enough for the two bottom sawyers who remain to be placed beneath it.

When operating in the timber yard where they usually find assistance in raising very heavy parts; they normally use two strong trestles C D (Fig 1.); and when they have sawed one end of the workpiece, such as, for example, at E, they separate trestle C from trestle D, & then they work between these two trestles, which are very convenient for this operation, whenever they have the assistance in mounting the workpiece on top.

But it often happens that the sawyers find themselves alone in the deal, where it would be impossible to raise heavy parts on such trestles; in this case they build for themselves a chevalet, which is a very simple trestle, nevertheless very solidly constructed.

They take for this purpose a timber log (Fig 3.); on which they make notches with their hatchet a b, f g, slightly oblique to the axis of the log, so that the legs of the trestle diverge at the bottom: the notches are more narrow at the top side of a & b, than the side of f & of g, that is to say, from below, so that the legs can not enter deeper than they are currently driven.

These notches are also wider than the bottom entry, so that the feet, whose tips form a kind of dovetail, can not get out of the notch. One makes three such notches, one in a, the other at b, & the third at d; which is merely punctuated in the figure, because it is hidden behind the part of the log that is the top of the trestle one can not view here.

The legs of this trestle are formed by three pieces of wood similar to the one labeled c e; they are round along their entire length, except at the upper end c which is squared, so that the face must fit the bottom of the notch, wider than the front. It is understood that because the tip c is wedge shaped, when the feet are driven by blows of the beetle, by this force into the notch, they are firmly secured by a dovetail joint: once in place these three legs form a sturdy trestle C (Fig. 2).

It is a question then, how to raise the piece of wood onto this trestle or chevalet, that is to be divided by the saw, such as, for example, that shown at D, and as these sort of pieces are usually quite large and heavy, the three long sawyers must exercise skill and strength to succeed.

In this case they build an inclined plane composed of two long planks of wood, which are placed with one end on the chevalet and the other on the ground; then they slide the workpiece to be sawed up this inclined plane, they rotate it, & having put it askew & balanced on the chevalet, they bind it to the planks G H, with the ropes E F. When this piece is sawed beyond half the length, they turn it around, & always maintaining balance on the chevalet, they bind the sawed half to the same planks, and complete sawing the other half of the piece.

When they must saw a piece that is very large & too heavy to be lifted onto the chevalet, or when they do not want to take the trouble, they dig a hole in the ground, in which the two bottom workers must pull down the saw.

Before mounting the piece to be sawed on either trestles or the chevalet, the workers mark the strokes they must follow for their buyer (see fig. 4): these strokes are marked with a line or cord rubbed with straw charcoal slurried in water, then the workpiece is carefully chocked plumb on the chevalet, and for this, one views a plumb bob opposite the eye.

Since it is the worker on top who guides the saw along the line, he must be more attentive than the other two, his work is also very tiring, because it is he who pulls up the saw.

At each stroke of the saw, the sawyers below must stand at first perpendicular, & as it descends they pull the bottom of the saw to themselves; the one from the top draws the top of the saw to himself at the same time; so that the cutting edge of the saw describes a curve necessary to clear the top line of the saw dust that is separated from the wood.

Every time the worker raises the saw, he backs off a little, so that the teeth do not rub their points against the wood, which would be very fatiguing, because his arms are not at a point of strength, when they raise the saw. To make the sawing even more fluid they occasionally rub the plate with grease, & they drive a wedge into the opening of the kerf that is already begun, which, combined with the path that is given to the saw teeth, gives a lot of play to move back and forth. When the sawyers drive their wedges too much, they force the wood fibers, which often causes splinters that damage the pieces: The joiners encounter these splinters when they are working the sawed lumber with a jointer plane.

The plates for long saws are of different thicknesses: the first are very thick, and they are more resistant than the others, but they make very wide kerfs in the wood: others are thinner and better prepared, they make thin kerfs, & pass more easily into the wood; but it must be used sparingly, above all when working cross grained and figured woods, ordinarily it is used for ripping wood in the timber yards, & the thicker saw plates are used when working timber in the forests: they are even employed in the largest saws that are powered by water.

Although almost always used to saw straight, sometimes they are used for sawing curved wood, either in the direction of their curvature (fig. 5), to make planks, or perpendicular to the curvature (fig. 6), to make turning pieces.

Henri-Louis Duhamel du Monceau

De l’exploitation des bois – 1764

—Jeff Burks