Editor’s note: Jennie Alexander and Peter Follansbee have been working on “Make a Joint Stool from a Tree” for so long that it is hard to pin down the exact date when they commenced. Now that this book is in the works at the printer, I asked Peter if he would mind discussing how he and Jennie chose the joint stool as the focus of this book. Here’s the story along with some snapshots from the historical record.

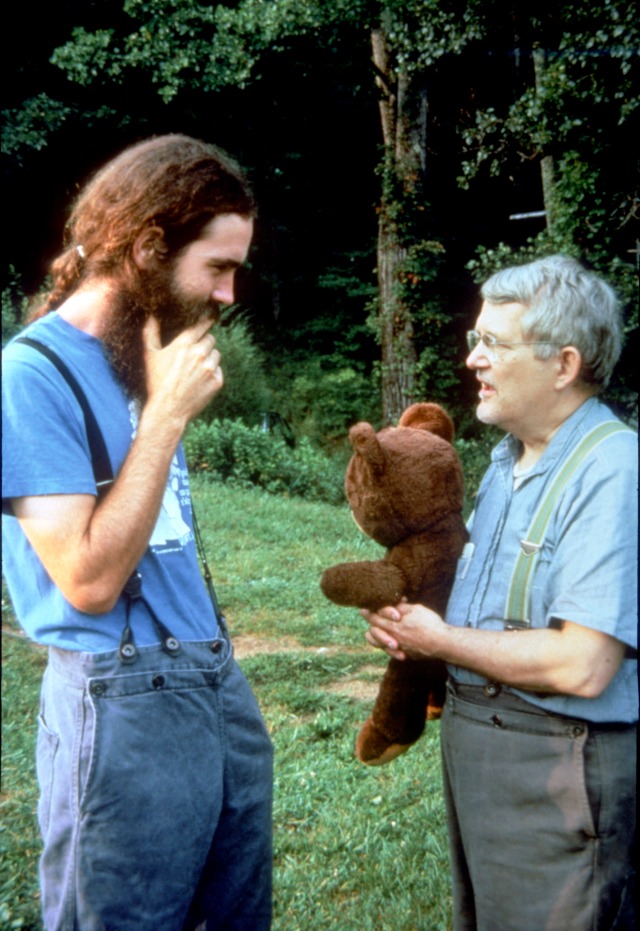

If you have heard me talk or write about the joint stool book, then you know it was a work in progress for a long time. More than 20-years-long time. So long ago that I looked young. Jennie Alexander and I decided early on to focus some of our efforts on making joint stools for a couple of reasons.

If you have heard me talk or write about the joint stool book, then you know it was a work in progress for a long time. More than 20-years-long time. So long ago that I looked young. Jennie Alexander and I decided early on to focus some of our efforts on making joint stools for a couple of reasons.

One factor driving our decision was the one-week workshop format. When I first got hooked on the prospect of being a joiner in the 17th-century style, Alexander was pitching the idea of a class to Drew Langsner, director of Country Workshops. One scenario had the students building a joined chest together – one week, 10 students, one log, one chest. I was game; Drew waited. He wanted Alexander to build a chest before he would commit Country Workshops to the possible lunacy of it all. At that point, it was all conjecture and test joints on Alexander’s part.

While the joined chest is perhaps the most appealing example of joined furniture, the joint stool is an icon. It reeks of the 17th century. The size and scope of a joined chest would take longer to make in numbers than it would to make a few joint stools. Knowing that repetition was one of the keys to really getting to know how joinery works, the stool became the main project for us to pursue.

And so the joint stool project was born. We each built a couple, then got Drew to take the plunge. Our first class in this work was 1991, I think. We taught it together a couple of times at Country Workshops, also at Jennie’s workshop in Baltimore. Once I got the job at Plimoth Plantation in 1994, mostly Alexander taught it alone.

I went on to build all manner of joined works, but the stool is surely the most-attainable project in a reasonable time frame for beginners. We chose it as the ideal introduction because it requires only a small amount of timber, whether you start with the log or not. And at 16 mortise-and-tenon joints, it’s enough to get a lot of practice, but not the 26 to 40 joints – or more – that might happen in a joined chest.

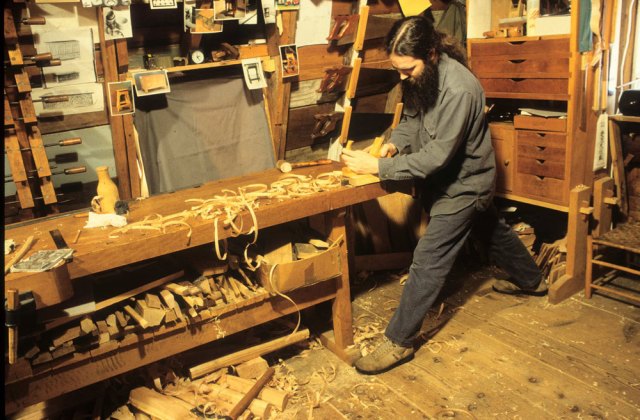

Looking back through old slides while researching what we might need for the book was quite instructive. Early on we used modern workbenches, here I am mortising a stile with it caught between bench dogs in a vise, before I had any good holdfasts to secure the workpiece. In this shot, you’ll see things you’ve not seen me do before: plastic-handled chisel, rawhide mallet, maybe even pencil marks on the stock. All of these eventually got chucked as we fine-tuned the process as well as the product. It worked; it just works better now.

Using the same German bench, I am planing stock also held in the vise. Back at this point, we knew about Joseph Moxon’s bench, but hadn’t yet built something like it. Once we built period-style workbenches, things changed all for the better.

One thing did not change – the power of the drawbored joint. Here’s Alexander driving pins in a stool frame. Hasn’t move a bit in over 20 years. And it won’t over the next hundred or more…

— Peter Follansbee

If you order “Make a Joint Stool from a Tree” before the press date of Feb. 27, 2012, you will receive free domestic shipping. For more details on the book, visit our store. The book is $43 and is produced and printed entirely in United States with 128 pages and more than 200 full-color photos.